All about Brushless DC Pump - A Definitive Guide

Estimated Reading Time: 6 minutes

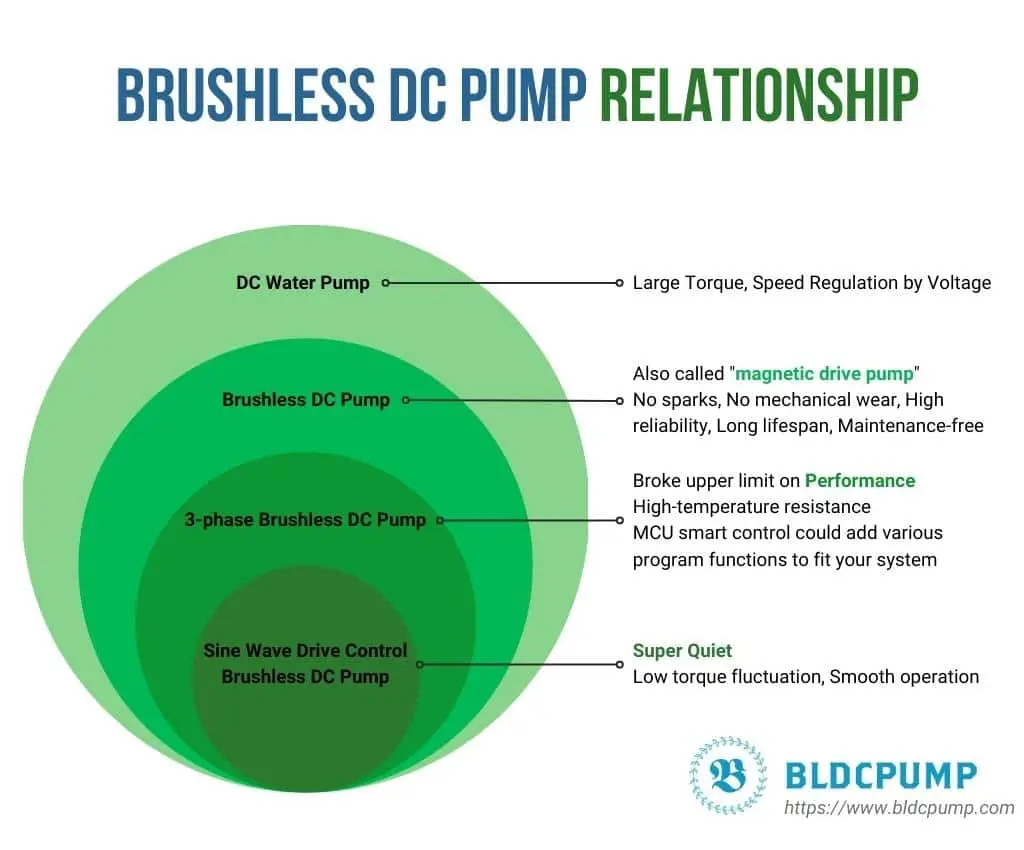

This article lists some important concepts of brushless DC pumps. At the end of the article, we use an infographic to give you a quick idea of how some of its confusing concepts relate to each other.

Why called brushless DC pump?

The brushless DC pump was initially named because of the use of a brushless DC motor. So let’s start with the DC motor development.

Pros and Cons of brushed DC Motor

The early DC motors were commutated by commutators and brushes, so it was called brushed DC motors as it was known to the public. It has the following pros and cons.

Pros:

Compared to the AC motor, the DC motor has excellent speed control performance, a wide speed regulation range, large torque, good low-speed performance, stable operation performance, and high efficiency.

Cons:

However, since conventional DC motors are commutated through brushes and commutator contacts, there are several drawbacks:

Sparks, Mechanical Wear, Electromagnetic Interference, Loud noise, Short Working Lifespan…

Due to the complex structure, the pump’s reliability is poor, easy to be failure, and frequent maintenance is required. In a complex system, it is an important source of the system’s unreliability, so its application is limited.

Pros of Brushless DC Motor

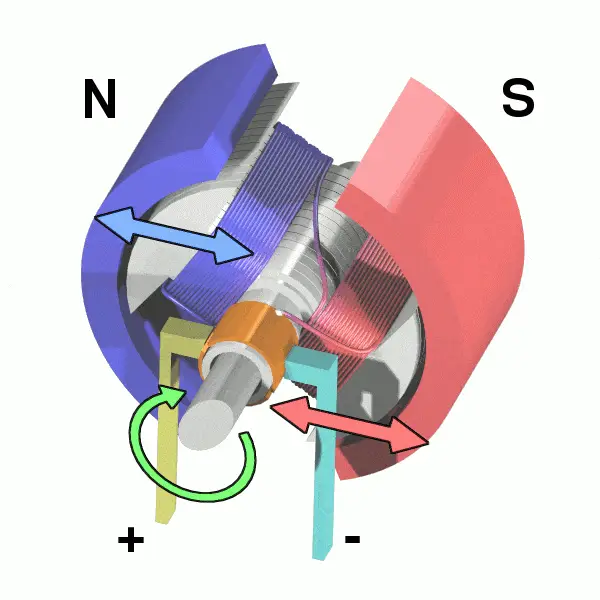

The invention of the brushless DC motor benefited from the development of electronic technology, which used transistor commutation circuits instead of brushes and commutators.

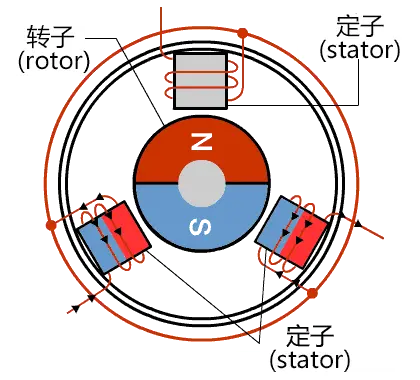

The structure of the brushless DC motor is similar to that of the AC permanent magnet synchronous motor, with coil windings on the stator and permanent magnets on the rotor.

Brushed Motor

Brushless Motor

Pros:

- Inherits all the advantages of brushed DC motors.

- No Sparks, No Mechanical Wear, High Reliability, Long Lifespan, Maintenance-free.

Structure Innovation based on brushless DC motors

The shaft seal failure and leakage is the most common reason for pump being burned. To completely solve this problem and prolong the service life of the water pump, the brushless DC pump has innovated the structure of the pump.

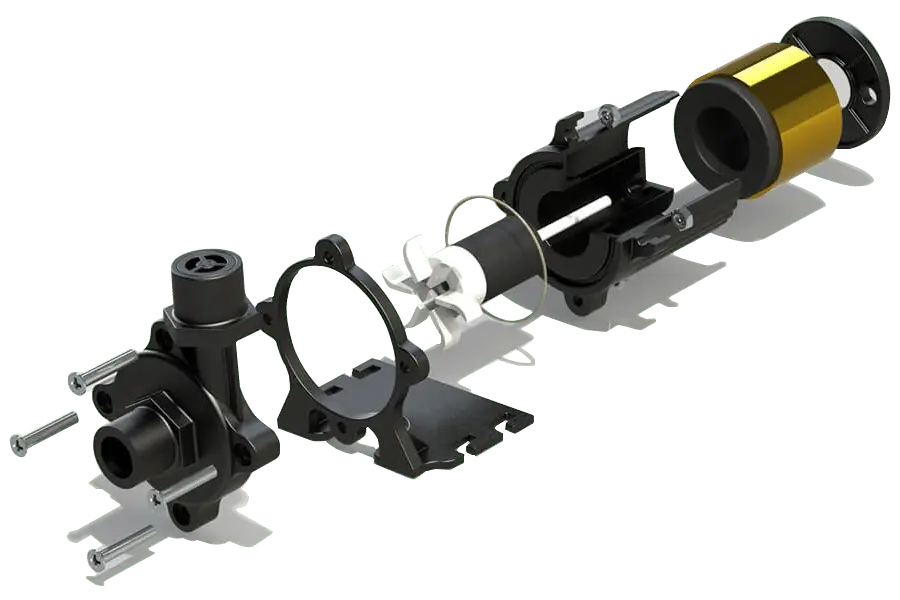

Structure of brushless DC pump (BLDC PUMP)

Rotor Fan - The rotor fan is driven by the magnetic field generated by the coil and works with the liquid. It is completely isolated from the stator coil and circuit board.

Ceramic Shaft - The quality zirconia ceramic shaft helps reduce rotation resistance and guarantees a long lifespan of the pumps.

Isolation Layer - The isolation layer is part of the pump body. It isolates the stator coil and circuit board from the rotor fan and liquid. And makes the pump completely waterproof.

Stator Coil - It generates a magnetic field to make the rotor running.

As you can see from the BLDC PUMP structure diagram above, the stator coil and circuit board are entirely isolated from the liquid and rotor by the isolation layer. Unlike the dynamic seal of the o-ring, this is a complete static seal. It guaranteed absolutely no leakage.

In addition to preventing liquid leakage, this structure also brings another benefit: good heat dissipation, which allows the pump to have a longer service lifespan. The pumping liquid medium cools the high-speed operation rotor, and the cooling efficiency is much better than the airflow cooling inside the traditional water pump.

Because of this unique structure of the brushless DC pump, it is often called another name: magnetic drive pump.

Difference between 2-phase and 3-phase

The working principle of the brushless DC water pump is similar to that of the AC water pump. That is, the rotor is driven to rotate by the changing magnetic fields generated by the paired winding coils on the stator. But please note that, unlike AC water pumps, brushless DC water pumps use low voltage DC power sources instead of 110V or 220V AC power.

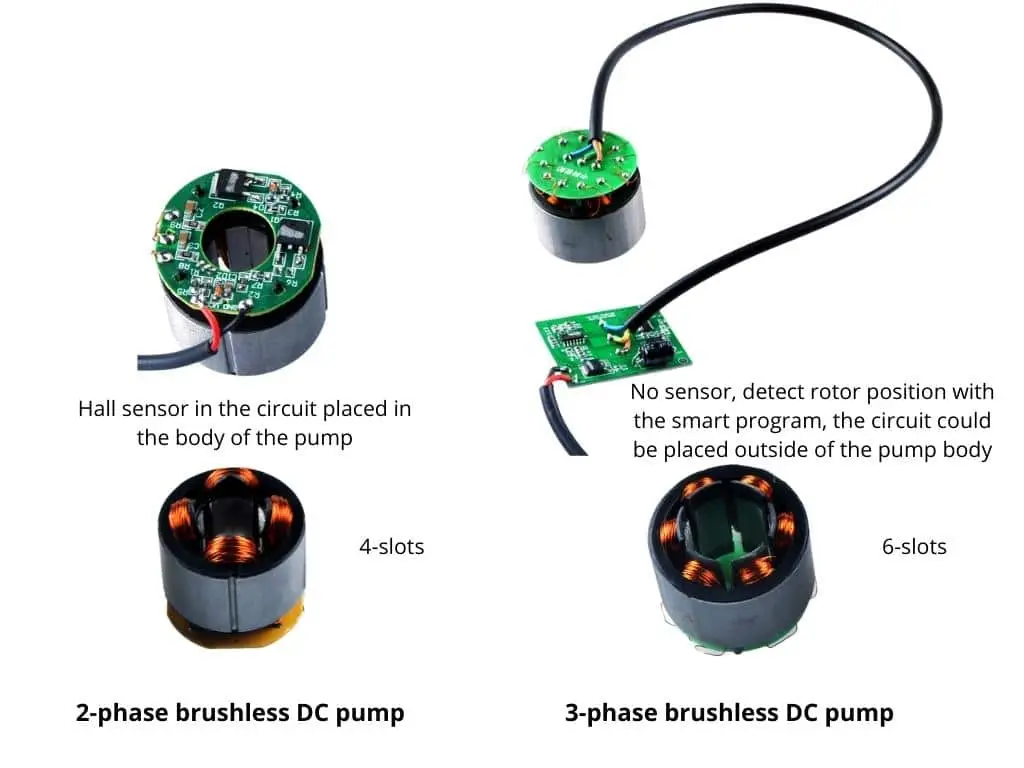

The 2-phase brushless DC pump has two pairs of magnetic fields and a 4-slots stator, while the 3-phase brushless DC pump has three pairs of magnetic fields and a 6-slots stator.

The 2-phase brushless DC pump usually has a lower cost than the 3-phase brushless DC pump. This is because it requires the circuit inside of the pump body to place the Hall sensor to detect the position of the rotor.

To ensure that electronic components are not burned, we usually require that the temperature of the medium being pumped cannot exceed 60 degrees Celsius. At the same time, the pump’s power should not be too large (because the winding coil itself will generate a lot of heat when the pump is working).

The 3-phase brushless DC pump use MCU control and intelligent commutation position detection in place of the Hall sensor. You can place the circuit with all electronic components in a control box outside of the pump body according to your needs.

Compared to a 2-phase brushless DC pump, a 3-phase brushless DC pump allow us significantly increase the pump’s rated power to improve the pump’s performance.

At the same time, the 3-phase brushless DC pump can work in a higher temperature environment.

In addition, due to the use of MCU, we can add many program functions to the pump, such as Reverse protection, stuck protection, over-current protection, manual speed control, gifted program, and so on.

The 3-phase brushless DC pump is a milestone upgrade, to sum up the above.

Sine Wave Drive Control - for noise reduction

Compared with the AC water pump and the traditional DC water pump, the noise of the brushless DC water pump is very low, about 40dB or less. However, in some particular environments, such as the plumbing mattress used in the bedroom, the circulation system of the fish tank, the cooling circulation system of the CPU, etc., our requirements for noise will be more critical.

To further reduce noise, we have adopted the sine wave drive control technology instead of square wave drive in some product models.

The principle of sine wave drive is as follows:

The pump’s control system obtains the precise position of the rotor by the 3-phase sensorless control technology. It uses the complex control circuit to provide the changing phase current matched with each opposite electromotive force. Ideally, using sine-wave drive control technology can achieve a constant pump torque.

As a result, compared with square wave drive, sine wave drive can achieve some advantages, including low torque fluctuation, smooth operation, super low noise, etc.

Because of the high cost, the sine wave drive control technology was mainly used in the military and in a few high-required applications. However, in recent years, due to the price reduction of high-speed MCU and DSP, it has received more and more attention.

Brushless DC Pump Relationship Infographic

With the advancement of various technologies and the continuous innovation of materials and processes, the performance of brushless DC pumps in all aspects has become more and more excellent. It has gradually become widely used in more and more fields in the past few decades.

It is the product of the combination of modern electronic technology (including power electronics, microelectronics technology), control theory, motor technology, fluid mechanics, and other disciplines.

Frankly, it’s not easy to sort out some of its concepts. So we wrote this article hoping it will help. The following infographic will give you a quick idea of how some of its confusing concepts relate to each other. If helpful, please enjoy and share.