Circulation Water Pump Manufacturer

Circulation Water Pump

Since 2009, BLDC PUMP has started to focus on excellent small circulation water pump R&D and production.

Designed to protect the core components within various types of equipment, our circulation water pumps adhere to stringent requirements such as 24-hour continuous operation, exceptional reliability, long-lasting durability, quiet performance, minimal maintenance, compact size, perfect adaptability to systems, and customizability.

Partner with us to build a flawless circulation or cooling system for your new project or product. We’re more than just a pump manufacturer; we’re your loyal business partner, committed to helping you earn both profits and a strong reputation.

15 Years of Real-Life Collaboration Gives Us the Edge

Before diving into the technical advantages of our brushless DC circulating pumps, know that our nearly 15 years of hands-on collaboration with various industries sets us apart. We don't just manufacture; we solve real-world challenges.

Unbeatable EMC Optimization

In today's miniaturization trend, EMI is a significant hurdle. Our expertise minimizes EMI, making your products compliant with stringent EMC standards. BLDC PUMP is your pathway to market leadership.

Specialized Cooling Solutions Beyond Water

Struggling with specialized cooling mediums like transformer oil? Your search ends here. We know water isn't always the answer. Our pumps can handle special mediums, thanks to our decade-long experience and R&D.

Just the Tip of the Iceberg

Just a few advantages of BLDC PUMP here. We offer tailored benefits for diverse industries. Our focus on customization sets us apart, as one size doesn't fit all in pumping solutions. Keep Reading and Explore More.

All You Need To Know About Circulation Water Pumps

What Is A Circulation Pump?

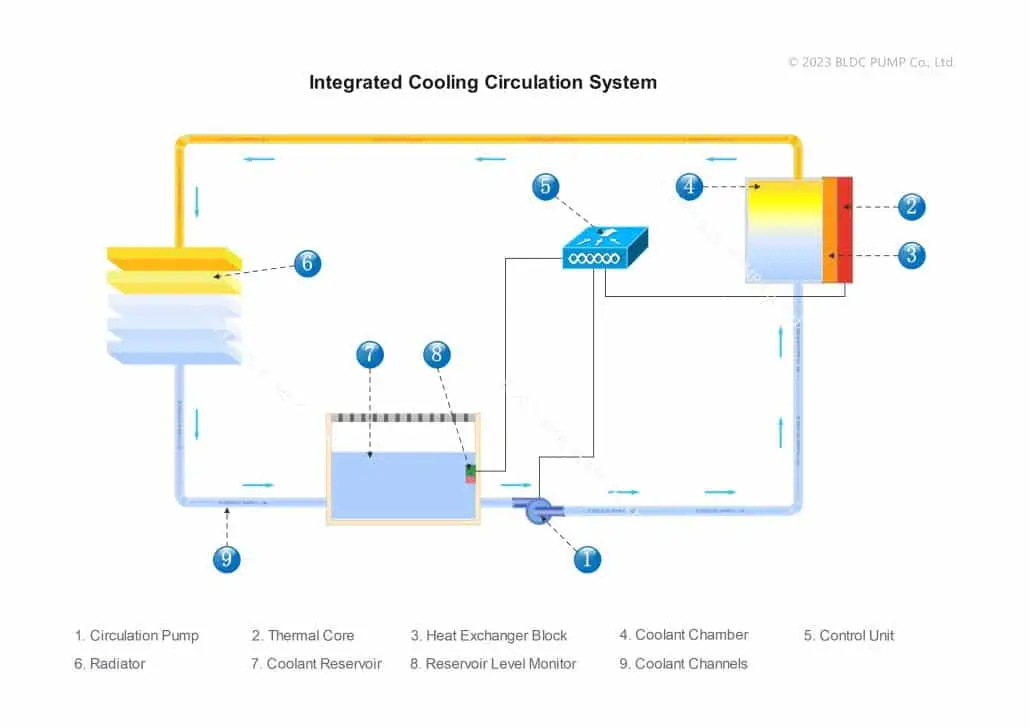

Following is a typical cooling circulation system inside of types of equipment.

A circulation pump is an essential component in the circulation system, responsible for circulating coolant through various parts of the system. It ensures the efficient transfer of heat away from critical components to a heat exchanger and radiator for dissipation.

The pump helps regulate temperature and optimize the system’s performance by maintaining a continuous coolant flow.

Circulation Pump Types

By Application

The pump used in the cooling circulation system above is typically known as a ‘Coolant Circulation Pump.’ Conversely, when used in a heating system, it’s often called a ‘Heating Circulation Pump.’

The target audiences for these two pump types differ significantly. Coolant Circulation Pumps are primarily aimed at manufacturers producing equipment, whereas Heating Circulation Pumps are geared towards fulfilling the domestic needs of end consumers.

By Mechanism

While you can use various types of water pumps for circulation, each has unique features. Small electric DC centrifugal pumps are increasingly favored for their durability, compact design, energy efficiency, low noise output, etc.

Some clients choose diaphragm pumps as their circulation solution, notable for their high-pressure capabilities. However, they tend to have a smaller flow rate and shorter lifespan than centrifugal pumps.

Choosing the right circulation pump should be tailored to your equipment’s specific requirements. The next section offers further guidance.

How To Choose Circulation Pump?

“Imagine your products operating at high efficiency and absolutely safe status. The circulation pump plays a pivotal role in making this vision a reality. Keep reading to learn how to select the perfect circulation pump for your needs.”

Key Points for Choosing a Circulation Pump:

Flow Rate

Make sure the pump moves enough liquid for all important parts that need cooling.

Max Head

Fully consider the pressure loss in the system, take into account all pipes, elbows, filters and other components.

Reliability & durability

Remember the pump should be able to withstand long-time continuous work.

Physical Size

Ensure the pump fits in the space you have in your machine.

Noise Level

Think about how loud the pump is, especially if your product will work in a quiet area.

Compatibility

Ensure the pump is compatible with your machine’s control system, allowing for features like speed feedback, low-water protection, and damage alerts for comprehensive monitoring and control.

Others

Also consider temperature range, ease of maintenance, cost-to-value ratio, power usage, liquid compatibility, and so on.

How Important Is Circulation Pump

A Quality Circulation Pump is Crucial for Your Products

The circulation pump is more than just a component in your products; it’s a critical selling point. A top-tier pump elevates product reliability, boosts customer trust, and strengthens your brand.

Moreover, it significantly lowers warranty claims and repair costs while enhancing energy efficiency—a highly marketable feature. Overall, a quality pump increases the product lifespan, fostering long-term brand loyalty. Choose wisely; your product is only as good as its weakest link.

To help you make an informed decision based on your needs, the following table shows a comparative overview of different water pumps used as circulation pumps.

| Feature/Attribute | AC Pumps | Common DC Pumps | Diaphragm Pumps | Brushless DC Pumps |

|---|---|---|---|---|

| Power Source | Alternating current | Direct current | Direct current | Direct current |

| Efficiency | Low | Medium | Medium | High |

| Noise Level | Moderate to High | Moderate | High | Low |

| Life Span | Moderate | Moderate | Shorter | Long |

| Size/Compactness | Large | Compact | Varies | Very Compact |

| Flow Rate | High | Moderate | Low | Moderate to High |

| Pressure Capability | Low | Moderate | High | Moderate to High |

| Maintenance Needs | Regular | Regular | Frequent | Less Frequent |

| Cost | Moderate | Low to Moderate | Varies | Higher Initial Cost |

| Application Suitability | General Purpose | General Purpose | High Pressure Tasks | Specialized Tasks |

| Durability | Good | Moderate | Moderate | Excellent |

| Energy Consumption | Moderate to High | Moderate | Varies | Low |

| Compatibility with Control Systems | N/A | Good | Varies | Excellent |

| Built-in Electronic Controls | No | Sometimes | Sometimes | Yes |

| Variable Speed Capabilities | No | Yes | Limited | Yes |

| Self-Protection | No | Limited | Limited | Yes |

The Installation Of Circulation Pump

1. Install the circulation pump below the coolant reservoir level to prevent dry running and potential burnout. Use a water level detector and ensure the pump has dry-running protection. Refer to the integrated cooling circulation system diagram mentioned previously.

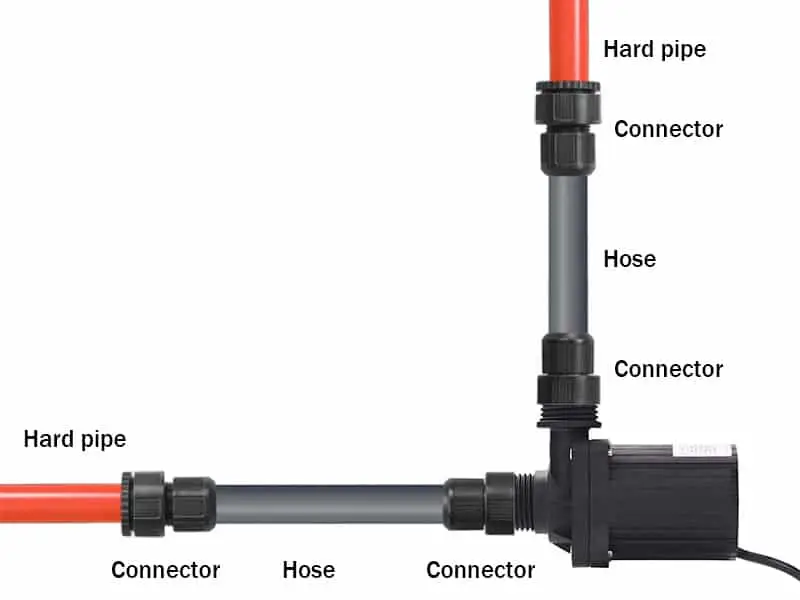

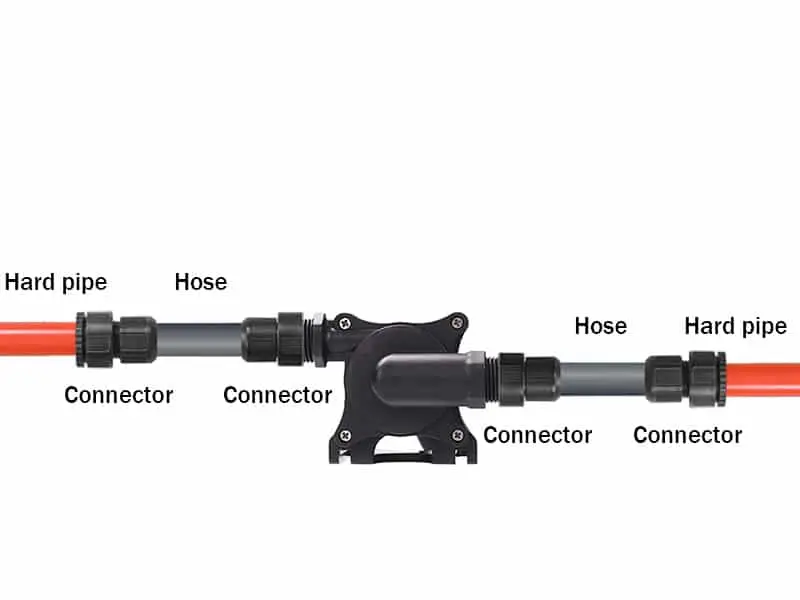

2. Select the right inlet and outlet angle to avoid bending or twisting. If necessary, open a pump mold for customization.

3. Use a hose to transition and seal material to ensure the connection does not leak.

4. Use shock-absorbing pads and screws for stable mounting and to prevent resonance.

5. Select a well-ventilated area for circulation pump installation to ensure efficient heat dissipation and facilitate easy maintenance.

6. Consult our technicians for additional installation attention.

The Lifespan Of Circulation Pump

How long does a circulation pump last? The rated lifespan of circulation pumps varies based on their distinct operating principles.

After choosing a specific circulation pump, its lifespan is influenced by various operational factors. Here’s a streamlined overview:

Usage Frequency: The daily duration of pump usage can impact its longevity. Continuous, heavy use without breaks can expedite wear.

Medium Purity: Clean media prolongs pump life, while dirty or abrasive substances can lead to clogging and increased wear.

Temperature & Environment: Pumps operating in high temperatures or submerged settings must be specifically designed for those conditions.

Operational Load: Avoid overloading the pump beyond its capacity, as it can cause overheating and faster wear.

Regularly monitoring these aspects and adhering to maintenance protocols can ensure the pump performs optimally for an extended period.

Circulation Pump Custom Solutions

If you’re selecting a circulation pump for your new product, a tailored solution can make all the difference.

Starting with a standard circulation pump for sample testing is a great way to evaluate pump quality, but once you decide to move to mass production of your products, customization is key to ensuring the circulation pump seamlessly integrates into your system.

For example, you may need to adjust the pump’s external dimensions to fit within the limited space of your equipment. Altering the direction and size of the pump’s inlet and outlet could be essential for aligning with your system’s piping. Material changes to the pump body might also be necessary for corrosion or oil resistance.

Beyond that, customization options extend to operating voltage, flow rate, head lift, cable length, connector types, and additional control features. In short, a well-thought-out custom solution is a critical step in producing a flawless product.

“And the best part? Customizing your pump doesn’t have to break the bank. Discover our affordable customization services here.“

Common Problems And How To Fix

1. Check the power supply and connections.

2. Open the pump to check if the rotor is jammed.

3. Assess potential motor burnout or deformation of components.

1. Make sure no air is trapped in the circulation system.

2. Check any resonance between the pump and your equipment.

1. Maintain good ventilation around the pump area.

2. Prevent the pump from running dry.

3. Check the pump isn’t overloaded.

4. Monitor the temperature of the fluid being pumped.

1. Ensure the medium fills the pump without cavitation or air pockets.

2. Confirm that system pressure and resistance aren’t too high for your pump.

1. Inspect and tighten all connecting parts securely.

2. If the issue persists, contact the pump manufacturer.

BLDC PUMP: Powering Your Business 24/7 with Unmatched Durability and Reliability.

Say goodbye to business woes caused by low-quality components. As the backbone of your circulation system, our BLDC PUMP operates 24/7 with unmatched durability and reliability. Trust us, you’ll see the long-term benefits of using the best circulation DC water pumps on the market.