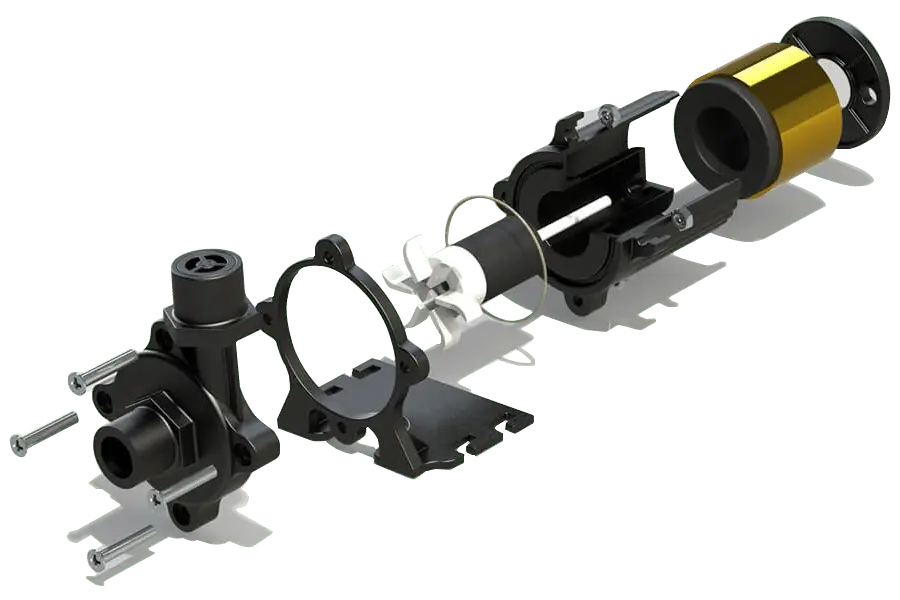

The Structure of BLDC PUMP

Rotor Fan - The rotor fan is driven by the magnetic field generated by the coil and works with the liquid. It is completely isolated from the stator coil and circuit board.

Ceramic Shaft - The quality zirconia ceramic shaft helps reduce rotation resistance and guarantees a long lifespan of the pumps.

Isolation Layer - The isolation layer is part of the pump body. It isolates the stator coil and circuit board from the rotor fan and liquid. And makes the pump completely waterproof.

Stator Coil - It generates a magnetic field to make the rotor running.

This unique structure brings two benefits:

1. The rotor fan is driven by magnetic force and does not require a commutator. It improves the efficiency of the water pump, avoids mechanical wear, and has no sparks.

2. As the core component, the stator coil and circuit board are entirely isolated from the liquid by the isolation layer, completely preventing leakage.

Continuously Innovative Technology

With no windings on the rotor, they are not subjected to centrifugal forces. And because the windings are supported by the housing, the rotor can be cooled by the conduction media, does not need airflow inside the motor for cooling. All of this means that the motor’s internals could be entirely enclosed and protected from dirt or other foreign matter.

The stator is potting by epoxy and separated from the rotor by an isolation layer. So the waterproof performance is reliable. This kind of pump is amphibious and maintenance-free.